Showing 17–32 of 148 results

FEATURES:

Largest Volume Press Brake Producer

Welded steel frame incorporates rigid stress relieved frames

Y1, Y2, and X axis

Durma CNC Advantage 2D Graphic Control unit

Excellent bending quality with X and Y motor drivers

650 mm length back gauge moving on ball-screwed shafts.

European tool holders

Hardened and ground tooling

Front sliding support arms with T-slots and Tilting Stop

Request a Quote

Durma maintains status as the world’s largest volume producer of metal fabrication machinery. Durma manufactures CNC press brakes, turret presses, punching machines, lasers, shears, ironworkers, plate rolls, angle rolls, and saws.

FEATURES:

Largest Volume Press Brake Producer

Welded steel frame incorporates rigid stress relieved frames

Y1, Y2, and X axis

Durma CNC Advantage 2D Graphic Control unit

Excellent bending quality with X and Y motor drivers

650 mm length back gauge moving on ball-screwed shafts.

European tool holders

Hardened and ground tooling

Front sliding support arms with T-slots and Tilting Stop

Request a Quote

Durma maintains status as the world’s largest volume producer of metal fabrication machinery. Durma manufactures CNC press brakes, turret presses, punching machines, lasers, shears, ironworkers, plate rolls, angle rolls, and saws.

FEATURES:

Largest Volume Press Brake Producer

Welded steel frame incorporates rigid stress relieved frames

Y1, Y2, and X axis

Durma CNC Advantage 2D Graphic Control unit

Excellent bending quality with X and Y motor drivers

650 mm length back gauge moving on ball-screwed shafts.

European tool holders

Hardened and ground tooling

Front sliding support arms with T-slots and Tilting Stop

Request a Quote

220 Metric/242 Ton, 22 kw / 30HP / 220V / 3 Ph / 60 Hz

FEATURES:

Largest Volume Press Brake Producer

Welded steel frame incorporates rigid stress relieved frames

Y1, Y2, X and R axis

Durma CNC Advantage 2D Graphic Control unit or

Excellent bending quality with X and Y motor drivers

650 mm length back gauge moving on ball-screwed shafts.

European tool holders

Hardened and ground tooling

Front sliding support arms with T-slots and Tilting Stop

Request a Quote

Durma maintains status as the world’s largest volume producer of metal fabrication machinery. Durma manufactures CNC press brakes, turret presses, punching machines, lasers, shears, ironworkers, plate rolls, angle rolls, and saws.

FEATURES:

Welded steel frame incorporates rigid stress relieved frames

Y1, Y2, X and R axis

Delem DA 66W Controller

Excellent bending quality with X and Y motor drivers

650 mm length back gauge Servo Motorized with Linear Guide & Ball Bearing System (X-R)

2-Front sliding support arms with T-slots and Tilting Stop

Protective Covers

World Class Hydraulics & Electrics

Request a Quote

DURMA’s 55 years of experience translates into product quality, innovative solutions, proactive approach and customer service excellence.

STANDARD EQUIPMENT:

Two-way 45° Angle Adjustable Clamp

Hydraulic Vice

Electronic Variable Cutting Speed Adjustment with Inverter

Bimetal Bandsaw and Cooling System

Blade Tensioning – Hydro Mechanical

Bearing and Carbide Tape Blade Housing

Cutting Height Adjustment

Motorized Roller Feeding

Request a Quote

Durma USA and its technical and sales support unit, SCA Fabtool Corporation, has served and supported the US metal fabrication industry since 1983.

FEATURES:

Flexible Roller especially for medium thick plate

Wide working range

Good value for precision and reliability

All three (3) rolls are driven with superior roll torque and speed

Request a Quote

Designed and engineered with modern technology, Durma products are equipped with high quality and proven readily available components.

Standard Equipment

Control Unit with DROs

Induction Hardened Rolls

Conical Bending

PLC Synchronized Side Rolls

Bearing Seated Rolls

Hyd. Top Roll Opening

Stress Relieved Frame

Pressure Adj. Bottom Rolls

Request a Quote

DURMA Ironworkers are well engineered, maximum efficiency and long life is guaranteed by latest manufacturing methods.

STANDARD EQUIPMENT:

Punch station with Durma adapter

Table for punching station

Durma quick change punch & die holder up to 40mm

1 starting set ( Punch & Die )

1m. Electrical back gauge

Blades for flat steel station

Blades for angle cutting station

Blades for round and square bar cutting station

Rectangular notcher complete with down holder

Table for notching station

Two foot pedals

More Information here!

Request a Quote

DURMA Ironworkers are well engineered, maximum efficiency and long life is guaranteed by latest manufacturing methods.

STANDARD EQUIPMENT:

Punch station with Durma adapter

Table for punching station

Durma quick change punch & die holder up to 40mm

1 starting set ( Punch & Die )

1m. Electrical back gauge

Blades for flat steel station

Blades for angle cutting station

Blades for round and square bar cutting station

Rectangular notcher complete with down holder

Table for notching station

Two foot pedals

More information here!

Request a Quote

220/440 Volt, 3 Phase, 60 Hertz, D-Touch “7” Screen Control

FEATURES:

World’ heaviest and most robust shear

Optimized cutting angle for minimized distortion

Oversized roller bearing guides and box constructed swing beam for constant blade gap over full cutting length contribute to straight cuts

Easy and low maintenance operation

Heavy duty ST44 A1 steel construction and stress relieved frame

7” CNC D-Touch 7 Touch Screen Control

One piece honed and chrome plated double acting powerful cylinders

High quality top and bottom blades.

Bottom: 4, Top: 2 cutting sides

Request a Quote

220 /440 Volt, 3 Phase

Durma USA and its technical and sales support unit, SCA Fabtool Corporation, has served and supported the US metal fabrication industry since 1983.

FEATURES:

Robust machine frame is manufactured with rugged steel construction and machined after welding for rigidity

A strong frame and world class components provide a long machine life

Minimized straight edge by hydraulic adjustments

Low energy and maintenance costs because of friction free planetary swing guides

Powerful guide rolls

Set of Standard Hardened & Ground Rolls

Request a Quote

Durma USA and its technical and sales support unit, SCA Fabtool Corporation, has served and supported the US metal fabrication industry since 1983.

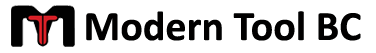

Features:

Siemens 840 D-ISL Control Unit

Solid & CNC Machined Steel Frames

Robust Bridge

CAD CAM Software with Auto Nesting

Cutting Plate Alignment Function with Laser Diode

Plasma Ignition Console

Request a Quote

Durma Hydraulic Swing Beam Shear

FEATURES:

Mono block, welded steel frame rigid to deflection moment and high tensile with ST44 A1 material.

CNC Touch Screen Control D-Touch 7

One piece honed and chrome plated double acting powerful cylinders

High quality top and bottom blades.

Bottom: 4, Top: 4 cutting sides

Easily adjustable blade gap adjustment system from single point

Fast and powerful back gauge with 1000 mm distance, moving by ballscrewed shafts, with automatic swing away feature

Request a Quote

Eagle Morlin Manufacturing is your industry leader for HVAC tools and machinery. We have been manufacturing and selling tools and machinery since 1983

Model 5400 – The MORLIN closing the “seam.” This new MORLIN

Ends Hand Hammering . . . Just a couple of taps at the center and ends of a standard length duct to secure the lock . . . then the MORLIN Versatile . . . Handles 30 to 22 gauge (no adjustment required). For straight runs, inside or outside radius . . . use it in the shop or on the job.

Request a Quote

Machines manufactured by elumatec are only put on the market if they meet our high standards in terms of reliability, efficiency, and accuracy.

FEATURES:

240-575 Volt, 60 Hz, 3 Ph Electrics (please specify)

2.7 HP Drive Motor

Horizontal Pneumatic Clamp

Vertical Pneumatic Clamp

Working range up to 250mm (9.85 in) wide

Depth distance stop for four different notch depths

Adjustable stop fence, can be swiveled left or right up to 60°

Positive pin location for 90° milling

Fast tool change through a spindle lock

Totally enclosed cutter set using a safety hood

Request a Quote